What is a

CNC Machine?

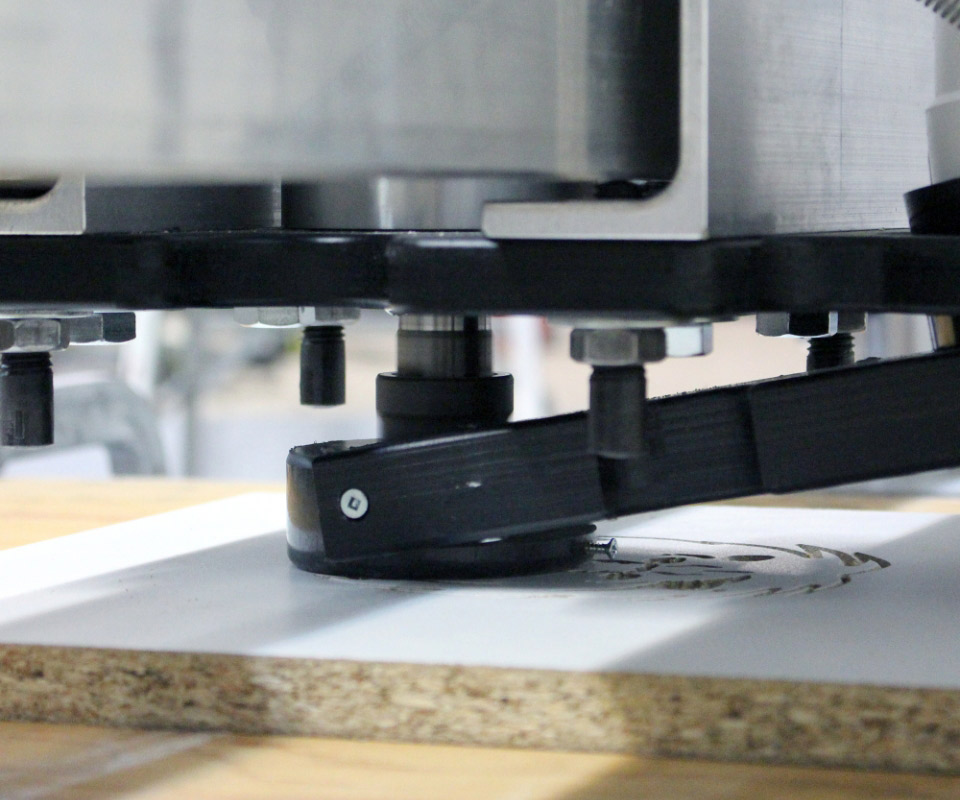

The numerically controlled table, better known as a CNC machine, is a computer-controlled machine tool, which gives movement instructions on the 3 axes: X, Y and Z. It allows the engraving, sculpting and cutting of complex shapes in various materials from a 2D or 3D vectorial template. The CNC provides results with superior accuracy, proven speed, increased safety and greater ease than with traditional machines. Thus, it is possible to produce customized parts such as furniture, signs, artistic objects or mechanical parts, and this, in various materials such as wood, styrofoam, plastic and aluminum.

Why a CNC Machine?

Compared to traditional machines such as traditional carving tools, round saws, band saws, etc., you gain in productivity and precision, while keeping control over your work thanks to our machine tool, all in a safe way. You simply need vector files, your material (wood, plastic, light metals), program the operations in CAD/CAM software and let the machine do its work. Our training, technical assistance and CAD/CAM drawing services are available to help you carry out your projects.

What types of work can be done?

One of the main advantages of the CNC is that it allows the production of all types of parts that can be machined on the 3 axes, by subtractive process: furniture parts, mechanical parts, musical instrument sculptures, company signs, etc.

Why a CNC Machine?

Compared to traditional machines such as traditional carving tools, round saws, band saws, etc., you gain in productivity and precision, while keeping control over your work thanks to our machine tool, all in a safe way. You simply need vector files, your material (wood, plastic, light metals), program the operations in CAD/CAM software and let the machine do its work. Our training, technical assistance and CAD/CAM drawing services are available to help you carry out your projects.

What types of work can be done?

One of the main advantages of the CNC is that it allows the production of all types of parts that can be machined on the 3 axes, by subtractive process: furniture parts, mechanical parts, musical instrument sculptures, company signs, etc.

CNC Router VS. CNC Milling Machine

A CNC ROUTER differs from a CNC MILLING MACHINE in several ways.

CNC ROUTER

Type of materials

Soft materials such as wood, plastic and aluminum

Axes

– Moves along 3 axes: X, Y and Z.– Execution of pieces with a certain depth or height in the Z-axis, which makes it more of a sculpture (2.5D) than a three-dimensional piece.

Speed

Router-like motor with a rotation speed of up to 24,000 rpm.

Work surface

Very large work surface (cutting table 4 feet × 8 feet or 1,219 mm × 2,438 mm)

Tolerance

From +/- 0.005 in (0.13 mm) to +/- 0.030 in (0.762 mm) for certain uses and materials

CNC MILLING MACHINE

Type of materials

So-called hard materials such as steel and titanium

Axes

– More than 3 axes, often 4, 5 or 6– Realization of complex three-dimensional parts (3D)

Speed

Rotational speed of 1,000 rpm, but with more torque (rotational force applied to an axis)

Work surface

Restricted work area for machining parts requiring more precision.

Tolerance

From +/- 0.002 in (0.051 mm) to +/- 0.00019 in (0.005 mm)

— WHY A —

Paquand CNC?

Each CNC router machine is entirely designed, manufactured, assembled and programmed in Québec, in our workshop. We can therefore afford to rent our machines at competitive prices and maintain them more easily with our technicians in case of problems. You should know that we have designed our machines to make them easier to use than the majority of other CNC machines available on the market.

- Rigid and lightweight construction;

- Fully dismountable and easy to reassemble for transport to smaller spaces;

- Easily repairable by our technicians;

- Turnkey machining service;

- Training on how to use the machine upon delivery;

- Preventive maintenance service for our CNC machines;

- Mobile (on wheels);

- Adjustable acceleration and deceleration;

- Suction system at the table for the suction of your materials during the cutting process, thus avoiding the need to fix the panels during machining;

- Self-calibration (X, Y and Z).

— WHY A —

Paquand CNC?

Each CNC router machine is entirely designed, manufactured, assembled and programmed in Québec, in our workshop. We can therefore afford to rent our machines at competitive prices and maintain them more easily with our technicians in case of problems. You should know that we have designed our machines to make them easier to use than the majority of other CNC machines available on the market.

- Rigid and lightweight construction;

- Fully dismountable and easy to reassemble for transport to smaller spaces;

- Easily repairable by our technicians;

- Turnkey machining service;

- Training on how to use the machine upon delivery;

- Preventive maintenance service for our CNC machines;

- Mobile (on wheels);

- Adjustable acceleration and deceleration;

- Suction system at the table for the suction of your materials during the cutting process, thus avoiding the need to fix the panels during machining;

- Self-calibration (X, Y and Z).

Materials

With our CNC machines, you will be able to carry out your cutting, engraving and carving projects on a wide variety of materials such as wood, hard or soft, plastic, styrofoam and various light metals such as aluminum. Materials and cutting tools are not included. You must therefore bring everything you need for your projects. We sell cutting tools, such as bits in the most popular sizes.

Types of Operations

Our CNC router machines offer several cutting types:

Flattening is the process of levelling the surface of a workpiece.

Cutting is an operation that aims to cut a part through its thickness in a partial or complete way.

The “pocket” is designed to empty the inside of a shape without perforating it.

The “VCarve”involves the use of an arrowhead tool, allowing, like a brush, to make extremely narrow lines and “V” grooves.

Sculpting allows the shaping of complex 3D shapes.

Engraving is an operation which aims to remove, using a very pointed tool and in a very light way, the top of a surface to write or draw on it as with a pencil.

Digital Files

From 2D or 3D digital files, you will be able to transform your projects into a concrete result. No need to be a programming expert, all you need are your digital files on a USB key. We recommend that you design your files in vector or 3D according to your needs and then export them in .dxf format. Make sure to clean up your vectors, attach your anchor points and avoid duplicates that could create problems.

Frequently used compatible files:

Vectorial: .dxf, .eps, .ai, .dwg

3D : .obj, .stl

Software:

3D : Autodesk Fusion 360° (CAD et CAM Personnel – 1 an), FreeCAD, SolidWorks, AutoCAD, Sketchup, MeshCAM

2D : Adobe Illustrator, QCad, AutoCAD, Vectric, Vectr, LibreCAD

If needed, Paquand provides you with self-service work computers or a workspace for your personal laptop. We also offer technical drawing services for optimizing or designing your more complex projects*.

*Delays of execution may apply.

Equipment

Available on site:

Choice of a CNC format: 4 × 4 or 4 × 8

CAD/CAM design software

Worktables for assembly

Free parking

Free Wifi

Safety goggles/visors although you may also bring your own.

Earplugs

Here are the power tools that are available to the public:

Basic tooling (subject to availability)

Portable jigsaw

Portable vibrating blade

Portable drilling machine

Portable orbital sander

Portable screwdriver

Glue gun

Rotary tool (Dremel type)

Not available on site:

Work clothes, work shoes;

USB key with your file-ready for carving/cutting/engraving;

Materials with which you wish to carry out the work;

Work tools necessary for the accomplishment of your project;

Basic CNC cutting tools such as cutting bits (can be purchased locally at varying prices depending on the bit).

Cutting Tools

Our machines can use various types of bits according to the type of cut best suited to your project:

Ball Nose

The Ball Nose est un is a cutting tool with a rounded profile at its end.

(Suitable for carving operations.)

End mill

The End mill is a cutting tool with a flat end profile.

(Suitable for flattening, cutting and pocketing operations.)

V-Bit

The V-Bit milling cutter is a cutting tool whose profile is in the form of a V with an angle ranging from small to very pronounced.

(Suitable for engraving and grooving operations.)

Interested in our Paquand CNC machines ?

Discover our self-service option to rent our CNC machines.

Contact Us

740, boulevard Industriel, local 32

Saint-Eustache (Québec) J7R 5V3

514 418.6155

info@paquandcnc.com

Follow @paquand